Boiler Flue Gas Condensing Energy-saving Technology

Boiler Flue Gas Condensing Energy-saving Technology

Generally speaking, efficiency of the fuel and gas boiler can be calculated or verified according to the burning lower heating value. Fuel High Calorific Value = Low Calorific Value + Latent Heat of Vaporization from Flue Gas. High heating value of fuel is used for calculating lower heating value and latent heat of vaporization of flue gas moisture, which carries over 10% heat energy at least.

Basic on the above principle, we SYNERGY offer you import technology with experienced reference, to make the flue gas condensate fully or partially, and then use the heat out of condensation to heat the boiler make-up water, process hot water or domestic hot water, or to heat boiler combustion air, thus will bring you additional energy-saving benefits and environmental effects, enabling more than 10% fuels to be saved and more than 70% carbon emission reduced.

一. Direct Flue Gas Condensing Technology

-

Heat-exchanging medium is boiler feeding softened water or other process cold water to be heated.

-

Indirect heat exchanging between the flue gas and cold water.

-

Temperature of flue gas can be reduced down to 70℃.

-

The softened supply water can be heated to about 65℃.

-

Each boiler is equipped with one set condensing economizer.

-

Without additional air blower for flue gas discharge

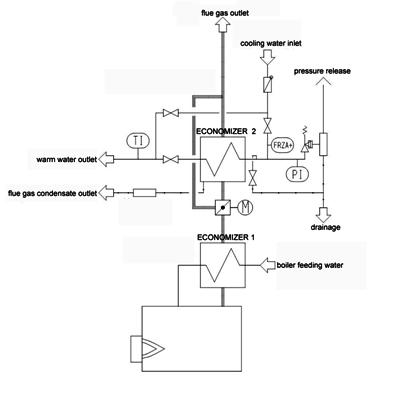

二.Indirect Heat-exchanging Flue Gas Condensing Technology

-

Economizer cooling water will be circled and recycled

-

At the side of secondary water, heat-exchanging medium is boiler feeding softened water or other process cold water to be heated.

-

The circled and recycled cooling water could be mixed directly to flue gas, and the heat exchange will be realized by external heat exchanger between make-up water and condensing water from Economizer.

-

Temperature of the flue gas can be reduced down to 30℃.

-

The softened supply water can be heated to about 55℃.

-

One set condensing economizer could be available for multi boiler.

-

Additional air blower is needed to discharge the flue gas.

-

Make use of the heat energy to heat combustion new air of the boiler.