Steam Technology History

Invention and using of the steam engine and power technology lead to the two industrial revolutions, which have great impetus to the course of human history. The existing widely used steam technology also results from that. Here, we would like to introduce steam technology history through the two industrial revolutions.

The First Industrial Revolution

From 1760s to the middle of the 19th Century (Human beings began to enter into the Steam Age)

The industrial revolution can be only attributed to genius of the small part of inventors. It is undoubted that genius matters but the most important is that many favorable forces were combined in the late 18th century. Apart from being stimulated by the strong needs, inventors seldom made inventions. A great many of principles, as the basis of various new inventions, had been known for centuries prior to the industrial revolution; but due to shortage of stimulation, they were not applied to the industry. So is the case of steam power. Steam power was known by people in Ancient Egypt in the Hellenistic Age and even had been applied but it was only used for opening and closing the door of the temple. However, in England, in order to pump water from the mine and rotate the wheel of the new machine, a new power was urgently needed so a series of inventions and reforms happened. Finally, the steam engine suitable for batch production was developed.

The First Industrial Revolution

Those favorable conditions lead to occurrence of a series of inventions so as to make cotton textile industry realize complete mechanization by 1830. Among those new inventions, the water-power machine invented by Richard Arkwright (1796), spinning jenny invented by James Hargreaves (1770), and spinning mule invented by Samuel Crompton (1779) are extremely outstanding. The water-power machine can spin the fine but solid yarns in rollers. Through the Spinning Jenny, one person can spin 8 yarns at the same time, later 16 yarns and finally 100 yarns. The spinning mule is also called the “mule”. Considering that the spinning mule has combined advantages of the water-power machine and Spinning Jenny, all new spinning machines can fast produce the yarns far more than those made by weavers. One priest, named Edmund Cartwright, tried to correct such unbalance. He gained the patent right of the power loom driven by the horse in 1785 and then driven by steam in 1789, but his invention was rough and had no commercial benefits. However, through 20 years of improvement, its most serious disadvantages had been corrected. By 1820s, such power loom had basically replaced the weavers by hand in the cotton textile industry.

Just as the inventions on spinning can lead to the relevant weaving inventions, inventions in some industry can promote the relevant inventions in other industry. The new cotton spinning machine gives rise to the need on the power which should be more sufficient and reliable than that driven by the water wheel and horse. Around 1702, the original steam engine was made by Thomas · Newcomen and had been widely used in water pumping from the coal mine. However, compared with other power provided, it consumes more fuels so it was only applied to the coal field. In 1763, James · Watt, the technician of University of Glasgow, improved the steam engine invented by Newcomen and Watt had reached partnership with Matthew · Boulton, a manufacturer. Boulton was responsible for raising money for the extremely expensive experiments and initial models. It is proven that this undertaking is extremely successful. By 1800, when the basic patent right of Watt expired, there were about 500 Boulton-Watt steam engines in use, in which 38% steam engines were used for water pumping and the remaining were used for providing rotary power for the spinning mill, blooming furnace, flour mill and other industry. However, smooth invention of the steam engine can not be separated from the natural environment and social factors at that time. As early as 120 BC, in Ancient Egypt, someone had studied to use steam as power. According to statistics, in the next over 1,800 years, more than twenty inventors had tried to use steam as power, but they had not made the relatively perfect steam engines which can be widely used in production. Therefore, it was said that “if Watt was born one hundred years in advance, he and his invention would die”. It can be seen that environment is also very significant.

The milestone of the steam engine can never be overestimated because it provides method to control and use heat energy and supply impetus to machinery. Therefore, it ends human being’s long-term dependence on the animal power, wind power and water power. At this time, the huge new energy has been gained by human beings and soon human beings were able to develop other mineral fuels hidden on the earth: oil and gas. Thus, the trend began and such situation occurred: people in Western Europe and North America can gain energy respectively 11.5 times and 29 times than those in Asia. Such figure has obvious meaning in such world with the economic power and military power directly depending on energy gained. In fact, it can be said that in the 19th century, Europe’s domination on the world was based on more steam engine than any other means or power.

The new cotton spinning machine and steam engine need more supply of iron, steel and coal and such need can be met through a series of improvement on mining and metallurgy. Originally, iron ore is smelt in the small smelter padded with charcoal. The forest loss makes the manufacturer have to seek for the coal. At this time in 1709, Abraham Darby discovered that the coal can change to the coke just as the wood can become charcoal. The coke is proven to be as effective as the charcoal, but the former is far cheaper than the latter. The son of Darby developed the large air bellow driven by the water wheel so as to make the first blast furnace mechanically operated to greatly reduce costs of iron. In 1760, John Smeaton improved it and he got rid of the air bellow used by Darby which is made of the leather and wood and replaced it with a pump which consists of four metal cylinders equipped with the piston and valve and is driven by the water wheel. The more important is improvement made by Henry · Cott who has invented the “puddling” method to remove impurity in molten pig iron in 1784. He placed the molten pig iron in the reverberatory furnace and then stirred or “puddled" it. By this way, through oxygen in circulating air in the molten mass, the carbon can be removed from the molten mass and after carbon and other impurities are removed, the iron will be produced which has more toughness than the original fragile molten pig iron or pig iron. At that time, in order to keep pace with the increasing needs in the iron making industry, coal mining technology has also been improved. It is the most important that the steam engine adopts the mine to drain water. Additionally, in 1815, Humphry · Davy invented the safety lamp which has greatly reduced danger in mine exploration.

For various development reasons, by 1800, the coal and iron produced by England were far more than those produced by the rest of the world. More specifically, England had its coal yield increased to 12 million tons in 1800 from 6 million tons in 1770 and gradually increased to 57 million tons in 1861. Meanwhile, England had its iron yield increased to 0.13 million tons in 1800 from 0.05 million tons in 1770 and subsequently increased to 3.8 million tons in 1861. At that time, iron was so rich and cheap and can be used for common construction. Hence, human beings entered into not only the Steam Age but the Iron and Steel Age.

Development of textile industry, mining industry and metallurgical industry stimulates needs on the improved transportation facilities which can be used for shipping bulk coals and minerals. In 1761, the most important step happened: at that year, Duke of Bridgewater built the 7-mile canal linking the coal mines between Manchester and Wolseley so the coal price in Manchester fallen by half. Later, the Duke extended this canal to River Mersey and costs on it were only one-sixth of the price gained by the land carriers. The amazing results gave rise to canal development fever, which made England have 2500-mile canal in 1830.

The great Road Building Age occurred simultaneously with the Canal Age. Originally, the roads were very primitive and people can travel only on foot or riding a horse. During the rainy season, the wagon carrying goods can not be driven by the horse on such road. After 1850, a group of road building engineers: John · Metcalf, Thomas · Telford and John · McAdam, invented the technology to build and pave the hard surfacing which can stand transportation throughout the world. The speed of the wagon increased to 6 miles, 8 miles and even 10 miles per hour from 4 miles per hour and travelling at night became possible. Hence, travelling time from Edinburgh to London, reduced to present 44 hours from previous 14 days.

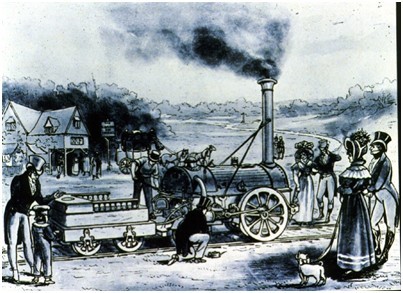

Since 1830, the road and waterway were challenged by the railway which was realized by two stages. In the first stage, it was the steel rail or iron rail which had been widely used in the middle of the 18th century and such rail was often used for shipping the coal from the mining opening to some waterway or coal firing place. It was said that on the rail, one woman or child can pull the goods van carrying 0.75 ton and one horse can carry the goods equal to those that 22 horses carry on the common road. In the second stage, the steam engine was installed on the goods van. The mining engineer, George Stephenson, made great contribution in this stage and he made use of one locomotive to pull several coal cars to River Tyne from the mining. In 1830, his locomotive “rocket” travelled 31 miles at the speed of 14 miles per hour and pulled one train to Manchester from Liverpool. Only in a few years, the railway controlled the long distance transportation and can carry passengers and goods at the faster speed and lower cost than the road or waterway. By 1838, England had already held 500 miles of railway, by 1850, 6,600 miles and by 1870, up to 15,500 miles.

Steam also applies to water transport. Since 1770, inventors from Scotland, France and America began to test the steam engine on the ship. The first commercial steamship was successfully built by Robert · Fulton, an American people. He went to England to learn painting but after knowing James · Watt, he began to study engineering. In 1807, his “Clermont" steamship sailed on the Hudson River and this steamship was equipped with one Watt steam engine driven by the paddle wheel. It sailed 150 miles from Hudson River to Albany. Other inventors also took Fulton as the example and the most famous was Henry · Bell in Glasgow and he laid foundation for the shipbuilding industry in Scotland at the both sides of River Clyde. In the early stage, the steamship was only used to sail on the river and sea. However, in 1833, the “Royal William” steamship sailed to England from Nova Scotia. Five years later, the “Sirius” and “Great Western” steamships sailed across the Atlantic Ocean at the opposite direction, respectively taking 16 and half a days and 13 and half a days with their travelling time about half of time required by the fastest sailing ship. In 1840, Samuel · Cunard built one fixed shipping line across the Atlantic Ocean and announced the arriving date and departure date of the ship in advance. Cunard advocated that his shipping line had replaced the irregular “ocean railway” which can not be separated with the sailing ship but make people irritating. By 1850, the steamship had surpassed the sailing ship in terms of carrying passengers and parcel posts, successfully winning freight transport.

The Second Industrial Revolution

From the second half of the 19th Century to the early 20th century (human beings began to enter into the age of electricity, reaching peak in the information revolution and news revolution.)

The Second Industrial Revolution

The industrial revolution started from the late 18th century has stably and tirelessly continued to present. In fact, it is arbitrary to classify its development course into different periods. However, if taking the year of 1870 as the transition period, it can be classified. Around 1870, two major developments occurred so that science began to have increasingly important influence on the industry and plenty of production technology had been improved and applied.

As we have mentioned in the above chapter, science has no influence on the industry at the beginning. Among the various inventions that we have mastered in the textile, mining, metallurgical and transportation industries, seldom of them were made by scientists. On the contrary, most of them are completed by the talented technicians who have responded to stimulation of extraordinary economy. However, after 1870, science began to play a more and more important role and gradually it became an integral part of all large industry production. The industrial research laboratory was equipped with the expensive instruments and provided with well-trained scientists who would conduct systematic study on the specific issue and such laboratory replaced the attic and workshop of the lonely inventors. In the past, invention was the result that the individual made response to the opportunity, but nowadays it is planned ahead and actually customized. Walter · Lippmann has correctly described this new trend as follows:

Since the earliest times, there were machines invented and they are extremely important, such as the wheel, sailing boat, windmill and water wheel. In modern times, the methods for making inventions and discoveries have been produced. The mechanical advance does not exist by chance or by accident but it is systematic and increasing. The belief that we know we will produce more and more perfect machines has not been recognized by previous generations.

After 1870, all industries are influenced by science. For example, in the metallurgy industry, many processes (the Bessemer process of steel production, Siemens-Martin steel making method and Thomas-Gilchrist process) have been invented so that the low-quality iron mine produces plenty of high-grade steel. Based on that the combustion motors mainly using oil and gasoline are invented by electricity, the power industry has been thoroughly reformed. The communications have been improved due to invention of wireless technology. In 1896, Guglielmo · Marconi invented the machine which can transmit and receive information without needing the wire, but his achievement was based on the research of James · Clerk · Maxwell, the Scottish physicist and Heinrich · Hertz, the German physicist. Thanks to great efforts made by the geologists and chemists, the petroleum industry can develop so fast. The geologists can probe the oil field by the extraordinary accuracy and the chemists have invented various methods to refine the naphtha, gasoline, coal oil and light and heavy lubricating oil. One of the amazing examples that science has influence on the industry can refer to the derivatives from coal. The coal can produces not only the coke and precious gas for lighting but coal tar. From the coal, the chemists have found various precious derivates, including hundreds of dyes and other plenty of secondary products such as aspirin, wintergreen oil, saccharin, sanitizer, laxative, perfume, chemicals used for photography, high explosive, orange anthosin, etc.

The second stage of the industrial revolution is also featured with the development of mass production technology. America is leading in mass production just as Germany takes lead of science. America holds some obvious favorable conditions, which can demonstrate why America is leading in mass production: huge raw materials sources, sufficient capital supply from Native American and European people, continuous flow of cheap immigrant workforce, rapid population rise and increasingly improved living standards.

Two main methods of mass production were developed in America. The first method is to manufacture standard and interchangeable parts and to assemble them into the complete unit by small manual labor. Eli Whitney, an American inventor, started to use this method to produce muskets for the government in the 19th Century. His factory was built based on the new principle, which had drawn wide attention and was visited by many travelers. One of the visitors had given the proper description on features of Whitney's revolutionary technology: "he has made one mould for each part of muskets; it's said that those moulds are processed very accurately so that each part of any musket can apply to any other musket." Over decades after Whitney, the machine is manufactured more and more precise so it is likely to produce the completely same parts. The second method occurred in the early 20th century, which was about the "production line". Henry · Ford has won reputation and plenty of fortune because he has invented the annular transmission belt which can transmit the auto parts to the location as required by assembly workers. The development of such transmission belt has been vividly described as follows:

Production of the transmission belt was inspired by canned food workers in Chicago who lifted the beef cattle body along a row of butchers by the air crane. Mr. Ford tried this idea first when assembling the small parts of the motor and flywheel magneto and then when installing the motor and automotive chassis.

One day, one automotive chassis was bound on the cable wire. When the winch dragged the cable wire to the plant, six workers had a 250-feet historic travelling along with the cable wire. As they walked, they picked up parts on the way and fixed them on the chassis by the bolt. The experiment was done but one problem occurred. God does not create people as precise as Ford manufactures the piston ring. As for the short workers, the assembly line is too high but as for the tall workers, it is too low. Hence, it works fruitlessly.

Therefore, more experiments were done: first to lift the assembly line and lower it again and then use two assembly lines to suit workers whose height is different. Alternatively, to increase running speed of the assembly line and reduce its speed and then do various tests to determine how many people should be provided to each one assembly line, how far each process is apart from each other and if people screwing the bolt need to screw the nut so that the former one screwing the nut has time to tighten the nut. Finally, time on assembling the automotive chassis is reduced to one hour and thirty-three minutes from the specified 18 hours and twenty-eight minutes. A great number of new T type automobiles may appear in the world. As workers became the more effective "gear teeth" of the machine, mass production entered into a new stage.

Then, the advanced mechanical equipment was introduced to improve handling of batch raw materials. Mass production method has been enhanced in America and the best example can refer to the iron and steel industry. The following paragraph is to describe the manufacturing process of the steel rail of the railway to explain this method:

The iron and steel industry has developed the process production in the huge regional scope. The iron ore comes from Mesabi Range and the steam shovel ladles the iron ore to the train carriage which is dragged to Duluth or Superior. Then the train enters into some docks on the valley and when the bottom of the train carriage overturns outward, the iron ore is unloaded to the valley. Through the sliding way, the iron ore enters into the cargo compartment of the ore carrier from the valley. In Lake Erie Port, the ore carrier is unloaded by the automatic equipment and the iron ore is loaded into the train carriage again. In Pittsburgh, the train is unloaded by the two automatic unloading vehicles and the dump car rotates the train carriage to its side to make the iron ore fall into its compartment just as the waterfall. The skip car carries the coke, limestone and ore in the compartment to the top of the blast furnace and pours them into the furnace. Then, the furnace begins production. The molten iron charter transfers the still hot iron to the metal mixer from the blast furnace and then to the open-hearth furnace. By this way, the fuel is saved. Then, the open-hearth furnace will begin to produce the steel and molten steel flows into the huge steel ladle. After that, it will flow into the mould on the flat car which is pulled to several pits by one locomotive. After removing the mould, the steel ingot is barely left in those pits for heat preservation until the steel is rolled. The conveyor conveys the steel ingot to the rolling mill. The auto platform goes up and down from time to time to cast the steel rail with the form required between the rolling equipment so that the steel rail will have very good form. If some steel rails have little deviation, they will be given up. The power-driven crane, steel ladle, conveyor, auto dump car, un-loader and loading machine make the iron ore in the mine produce the steel rail, which seems to be inconceivably automatic and dynamic.

Along with the two industrial revolutions, the steam technology emerged at the right moment. Up to now, the steam technology involves all walks of life and is extremely significant to human life.

Major events of steam

In 2002, Oshina Keren made use of steam treatment equipment to study the mechanical property of the cryptomeria test specimen under the condition of overheated steam.

In 1999, Li Jie studied the steam activation of the pulsed discharge plasma.

However, on August 1, 1999, when the detector struck a meteor crater, no steam was found in the splash.

In April 1998, Anshan Design & Research of Coking & Refractories Institute designed the industrial gas production unit for Jiangxi Jindezhen Coking Gas General Plant and this technology took Yima long flame coal as raw materials, air and steam as gasifying agent to produce the industrial gas and realize the single boiler gas production ability. This technology was put into use in February 2001.

In 1997, this working group proposed thermodynamic property calculation formula of the industrial water and steam.

In 1997, Wang Liang’en adopted the combination technology of active carbon absorbing- desorption of steam-industrial water condensation to treat waste gas containing Benzene, Methyl Benzene and Dimethyl Benzene of Fuzhou City Plastics and Rubber Plant and Sneaker Workshop of Fujian Sanfeng Shoes Co., Ltd.

In January 1997, at the time when the sintering plant was shut down, a set of gravitate spray dust collector was installed to make use of density difference between flue gas of steam and air and depend on no external power to operate by natural ventilation.

The downstream overlap of the aluminum plate is glued with the glass cement and after sealed, the aluminum plate can not only have protective effect but act as the damp-proof course. Due to too many overlaps in the actual construction, the glue sealing is often not done well. The external steam in air is easy to penetrate into the polyurethane hole to lead to expansion and contraction and damage. Hence, we paid close attention to it in extension engineering of heat preservation on 12 large tanks in 1995.

The Remote Sensing Satellite launched by the European Space Agency in 1991 was equipped with two-wave microwave radiometry which was used to recover total water vapor contents in air to explain that surface temperature of ocean is influenced by air. The research on satellite-bone microwave radiometry began.

The Remote Sensing Satellite launched by the European Space Agency in 1991 was equipped with two-wave microwave radiometry which was used to recover total water vapor contents in air to explain that surface temperature of ocean is influenced by air.

In 1990, International Association for the Properties of Water and Steam (IAPWS) established a working group consisting of scientists from several countries to study the new calculation formula.

"Atmospheric type thermodynamic deaeration without using steam method" invented by Refinery of Sinopec Jinling Petrochemical Corp., Ltd. applied for the invention patent to State Intellectual Property Office of the PRC on March 12, 1986 and through five years of examination, State Intellectual Property Office of the PRC granted the patent for invention on December 12, 1990.

In 1984, 18 serious potential accidents were found out in the safety month and 10 of them had been corrected. The lifting loads of Casting Workshop of Xiangshan Metallurgy Machinery Plant were originally designed as 8 tons but due to frequent over-load operations, many roofing fissures occurred. The steel roof truss in water blasting room was eroded by steam and coal gas to lead to serious welded corrosion so that the external part of cement hanging bar peeled off.

In the middle of November 1982, the temperature of working surface corner reached 37℃ again and meanwhile steam and "sweat hanging" occurred. Therefore, it was obvious that coal would have spontaneous combustion.

It means that damp-proof course is not required but it can prevent wind and rain drop. The water vapor from human body can make it loss so it has the "breathing" moisture permeable and wind and rain-proof property. In 1981, Konebo Company developed Savina DP super-high density waterproof fabric.

Later, in 1975 and 1977, International Association for the Properties of Steam (IAPS) successively published the latest testing data sheet of the indentified viscosity and heat conductivity coefficient.

In February 1972, in the course of electrolytic tank pre-testing, because the capping is invaded by the 90℃ wet chlorine gas and salt water steam, less than a few hours bubbling and mono-block falling off occurred. The tank bottom has too many cracks due to bad-quality of cement maintenance. With the salt water permeating, the seam crossing of the positive electrode and the bottom have salt water and meanwhile pitch is softened to exude from the surface of the tank bottom.

In 1972, the corrosion resistance test of all covering layers of the sulphide ore thickener was conducted in the 80℃ medium containing hydrogen sulfide and steam.

Since in 1972, the first production type vacuum steam thawing unit developed by both England APV Company and Torry appeared, the thawing method entered into the application stage to play a crucial role in the thawing process of frozen products.

In 1971, in the effect gas, flying ash and steam escaping two-stage plan, in the 470 tons plant, one of the first plant to use PFR inspissator, a PFR inspissator was used to directly replace the contact evaporator of Hoerner Waldorf in Montana, America; meanwhile, a coal economizer and static plant was also installed.

The steam desorption fixed bed molecular sieve dewaxing technology independently developed by our country has the history of over two decades. From 1969 to present, five sets of production units for producing light liquid wax or heavy liquid wax have been successively established in Nanjing, Yanhua refinery plant, Daqing refinery plant, Jingmen refinery plant and Linyuan refinery plant.

The boiler thermodynamic calculation plan often refers to White Paper of Japan. The steam turbine is according to the simple thermal test (Specification of the Ministry of Water Resources of PRC) and its formula refers to White Paper of Japan. Water and steam equation of state adopts 1968IFC formula.

In 1967, this equipment was put into production and its operating medium is the coke, residual oil, oil gas, steam, etc.

In order to adapt to the above change, based on the IFC 1967 Formulation for Industry put by International Formulation Committee, we developed the thermodynamic property calculation software of the common water and steam to realize general computer solving of thermodynamic property of water and steam.

Preparation of thermodynamic property calculation general program of water and steam should be mainly according to the IFC 1967 Formulation for Industry. As for the incorrect areas, we adopt the formula made by Soviet Union Thermal Power Research Institute and make some change to some coefficients in the formula.

IFC Formulation was put out by International Formulation Committee in 1967. The existing steam property figure and table are based on the IFC Formulation.

Water and steam property table adopts the 1967 IWi Formulation

The calculation scope covers the whole scope as specified in the IFC 1967 Formulation for Industry put by International Formulation Committee in Sixth International Steam Property Conference.

Water and steam table calculation program adopts the internationally recognized IFC 1967 Formulation for Industry as calculation basis which can calculate saturation temperature, saturation pressure, enthalpy (h), entropy (s), specific volume (v) and exergy (e) of water and steam.

Based on Baker flow chart, in 1961, Goldman gained the flow chart of the adiabatic steam-water two-phase flow to make two-phase flow research enter into the stage of gas-liquid two-phase flow research.

In 1960, Zhou Chang and Mr. Yang Hongshi of Wuhan University used the warm water vapor in the common hot water bottle to deal with stalks in order to realize flower forcing.

In 1956, one plant built a tail gas absorber. When it was put into use and the vast white smoke emitted from the tail gas stack, people may be confused about it. In fact, because the tail gas absorber used ammonia water for circulating absorption, steam would be bound to produce and the white smoke was actually the steam, which was inevitable. 。

From 1954 to present, in just a few years, two international conferences had successively been held specially to discuss properties of water and steam

Since 1954, due to the atmospheric nuclear test, steam in air and nitrogen concentration in rainwater increasingly increase.

In 1941, Harteck from Germany, urey from America et al. put out the idea of producing heavy water through exchanging steam and hydrogen. Soon, the globally firs hydrogen–water isotope exchange method heavy water production plant was built in Norway.

In 1929, Miyata from Japan invented the steam sealing process on anodized aluminum oxide film. In 1931, the boiling water and potassium dichromate solution sealing method appeared in Europe, which laid the practical and technological foundation for the aluminum anode industry.

In 1904, Mollier from Germany put out the steam enthalpy-entropy diagram.

In the early 1895, Wilson adopted the method created by J.Aitken. Aitken found that gas rising from the flame can make steam in saturated gas deposit, so he called the unit which can make steam automatically condense as “dust recorder".

In 1705, Newcomen, a blacksmith from England, developed the first mine pumping steam engine.